Advanced Filters

Category

Subcategory

Featured

Get Started Kit

$69.95 (USD)

Highly Recommended for any first time Man Saver Post Driver purchase, so when your driver arrives...

DetailsFeatured

T Post Driver 98-E

$795 (USD)

Easy to use one person fence post driver. Runs off of any small air compressor that delivers at l...

DetailsFeatured

93-R Post Driver 2-7/8" Max OD

$1,129 (USD)

This post driver runs off any small air compressor that delivers at least 3.5 CFM at 90 PSI. Runs...

Details

Storage Bag

$24.95 (USD)

Dust and waterproof material.

1000 Denier Nylon - dust and waterproof.

1/2 inch nylon drawstrin...

Details

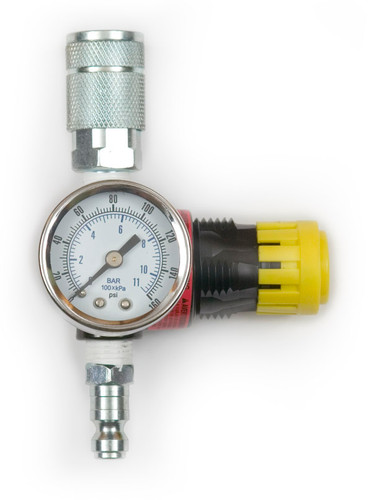

Inline Oiler

$29.95 (USD)

Use to oil your Man Saver. Features quick disconnect fittings. Catalog #104

Details

Hose with Fittings

$34.95 (USD)

50 feet long. 1/4 inch diameter air hose. Quick disconnect fittings.

All Orders Received PRIOR t...

Details

93-R Round Adapter

$49 (USD)

Round Adapter for 93-R Post Driver For any size smaller than 2-7/8” diameter To make our fence po...

Details

91-R Round Adapter

$49 (USD)

Round Adapter for 91-R Post Driver For any size smaller than 2-3/8” diameter To make our fence po...

Details

90-R Round Adapter

$49 (USD)

Round Adapter for 90-R-Series Post Driver For any size smaller than 2" To make our fence post dri...

Details